Titanium Felt LGDL: titanium felt liquid gas diffusion layer

LGDL: liquid gas diffusion layer

CL: catalyst layer

To reduce the interfacial resistivity between the LGDL and CL. There are two different surface treatments: sputter coating and thermal nitriding.

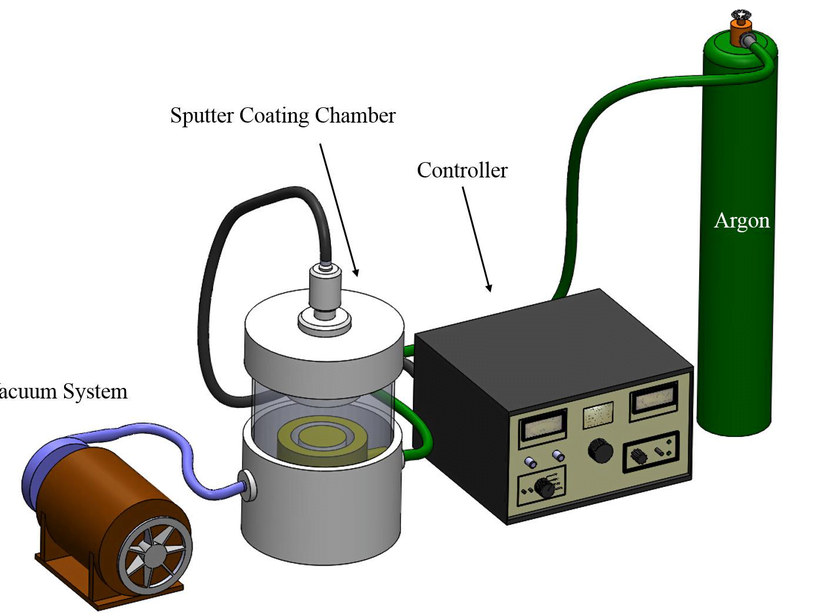

Sputter Coating

Firstly, as shown in Figure 1, sputter coating is a physical vapor deposition (PVD) method of thin film deposition by sputtering used to cover a specimen with a thin layer of conducting material. This involves ejecting material from a target onto a substrate. Resputtering is re-emission of the deposited material during the deposition process by ion or atom bombardment. Sputtered atoms ejected from the target have a wide energy distribution. The study will use 2.4KV to emit Au atoms from the target.

Secondly, the sputtered ions can ballistically fly from the target in straight lines and impact energetically. Alternatively, at higher gas pressures, the ions collide with the gas atoms that act as a moderator and move diffusively. At the same time, reaching the substrates or vacuum chamber wall and condensing after undergoing a random walk. The entire range from high-energy ballistic impact to low-energy thermalized motion is accessible by changing the background gas pressure.

The sputtering gas is often an inert gas such as argon. For effective momentum transfer, the atomic weight of the sputtering gas should be close to the atomic weight of the target. Therefore, in order to sputter gold plating on the titanium felt LGDL, the sputtering gas should be argon. After two depositions in one minute. A 200 nm film will appear on the surface of the LGDL fiber of the titanium felt.

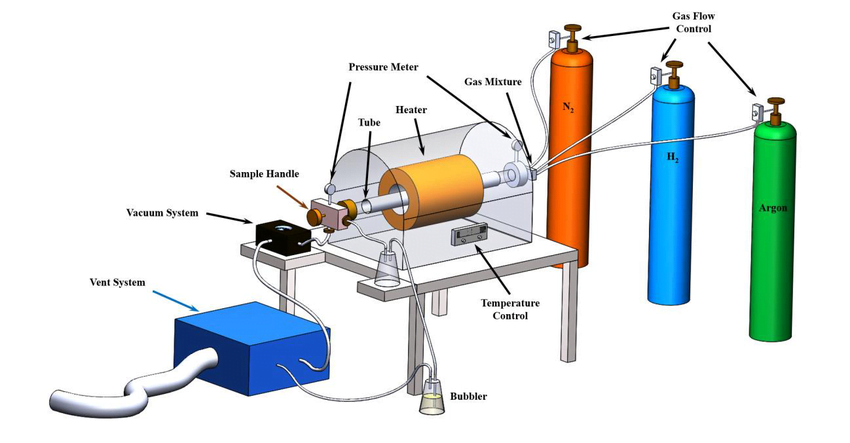

Thermal Nitridation

For the thermal nitridation of titanium, we use a chemical vapor deposition (CVD) process. As a result, in the thermal nitriding titanium felt LGDL, the titanium felt LGDL is visible. Nitrogen is absorbed by titanium at a constant temperature of 900 oC.

As shown in Figure 2, the thermal nitridation system mainly consists of high temperature furnace. At the same time, it also includes a Vacuum system and gas supply system. In this study, we placed the titanium felt LGDL in a nitrogen atmosphere at 900 oC for ten minutes. Finally, resulting in the growth of about 1 micron titanium nitride film on the surface of the titanium felt LGDL fiber.

After sputter coating Au and thermal nitridation surface treatment, all of the ti felt LGDLs were tested in a PEMEC. Therefore, by comparing the performance of the PEMEC with difference titanium felt LGDLs, we understand the influence of different parameters and surface treatments on the entire battery.

From 《Investigation of titanium felt transport parameters for Energy Storage and Hydrogen/Oxygen Production》

DOI: 10.2514/6.2015-3914