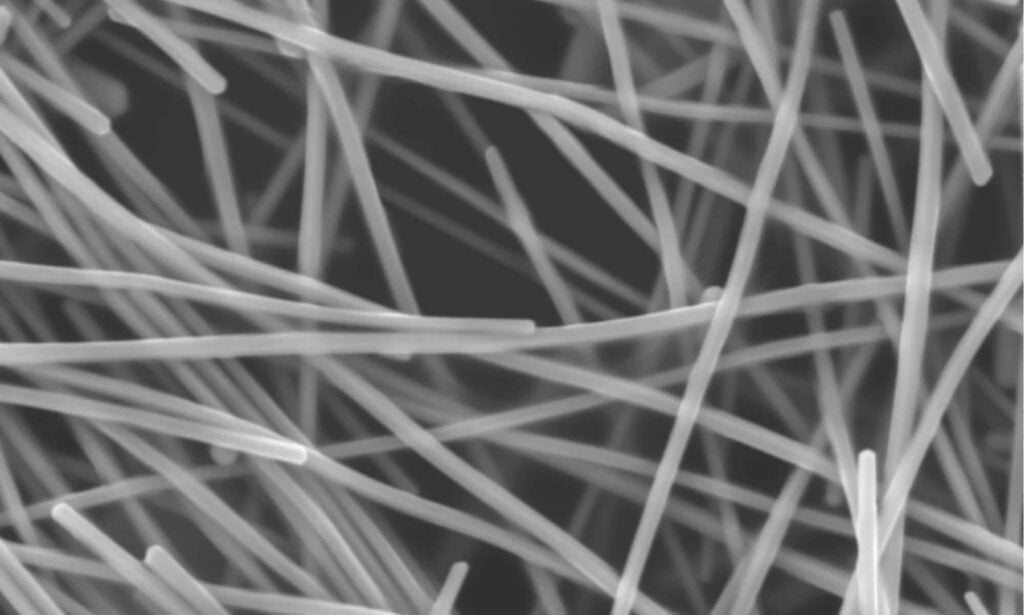

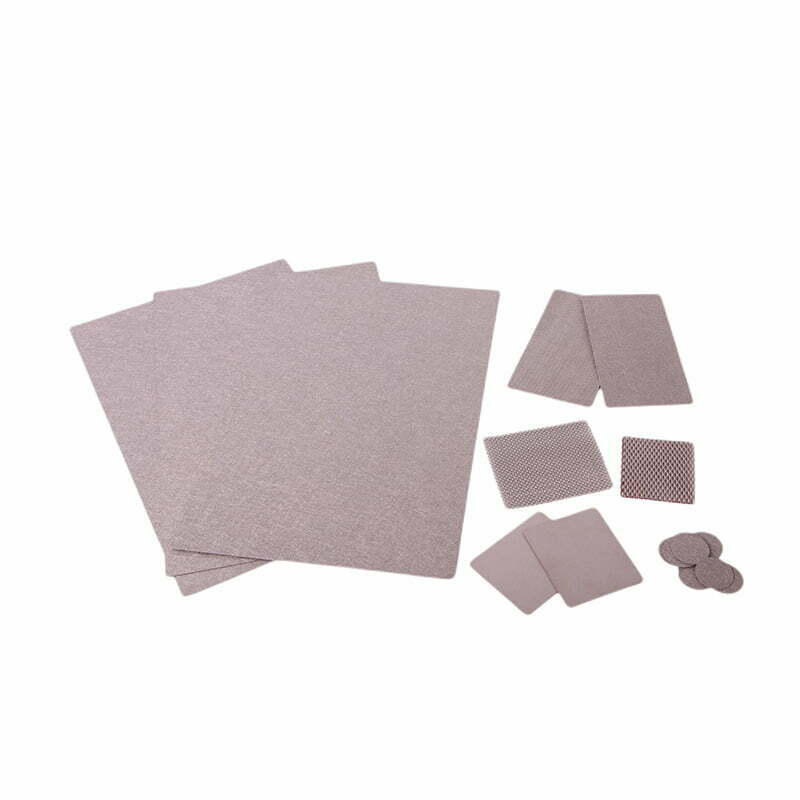

Titanium felt is a highly versatile material that has a wide range of applications in various industries. Including aerospace, chemical processing, and energy. This material created sintering titanium fibers together into a porous structure. resulting in a lightweight, high-strength material that exhibits unique mechanical and thermal properties.

One of the most significant advantages of titanium felt is its exceptional strength-to-weight ratio. It has a tensile strength similar to steel but is much lighter, making it an attractive choice for weight-sensitive applications. Additionally, the open-pore structure of titanium felt allows for greater heat transfer than solid materials, making it ideal for use in high-temperature environments.

Titanium felt is also highly corrosion-resistant, with excellent resistance to a wide range of acids, bases, and salts. This property makes it an ideal material for use in harsh chemical environments. Such as those found in the chemical processing and petrochemical industries.

In aerospace applications, titanium felt used for thermal insulation, as well as for structural components in aircraft engines and other high-temperature systems. In the energy industry, it used in fuel cells and batteries, where its high conductivity and corrosion resistance are crucial.

Overall, titanium felt is a unique and versatile material with a wide range of applications across multiple industries. Its exceptional strength-to-weight ratio, high thermal conductivity. and corrosion resistance make it an attractive choice for many applications. and ongoing research is likely to uncover even more potential uses for this remarkable material.

Here are some of the most common applications of titanium felt:

- Aerospace Industry: One of the primary applications of titanium felt is in the aerospace industry. It used for structural components in aircraft engines and other high-temperature systems, as well as for thermal insulation. Its high strength-to-weight ratio makes it an attractive choice for weight-sensitive applications.

- Chemical Processing Industry: Titanium felt’s excellent corrosion resistance makes it ideal for use in harsh chemical environments. It use in chemical processing equipment, such as tanks, pumps, and valves, as well as for filtration applications.

- Energy Industry: Titanium felt is also commonly used in the energy industry, particularly in fuel cells and batteries. Its high conductivity and corrosion resistance are essential for these applications.

- Medical Applications: Due to its biocompatibility and compatibility with MRI technology. The titanium felt is used in medical implants, such as artificial joints and dental implants.

- Heat Exchangers: The open-pore structure of titanium felt allows for greater heat transfer than solid materials, making it ideal for use in heat exchangers in various industries.

- Filtration: Titanium felt’s porous structure makes it an excellent filter material. It used in filtration applications where high temperatures and corrosive environments are present.