Introduction:

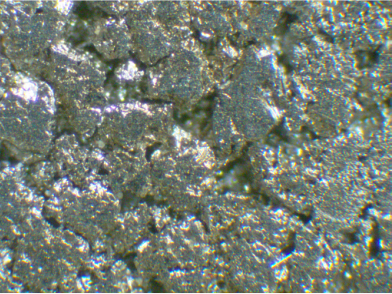

Titanium fiber felt composite microporous layers (TF-CMPL) have emerged as a promising material with a wide range of applications in various industries. This article explores the diverse uses and potential development prospects of TF-CMPL.

- Energy Storage: TF-CMPL finds extensive use as an electrode material in energy storage systems, such as batteries and supercapacitors. Its high electrical conductivity, large surface area, and interconnected pore structure enable efficient charge and discharge cycles. Integrating TF-CMPL enhances energy storage capacity and improves overall performance and durability of these systems.

- Catalysis: TF-CMPL is employed as a catalyst support material due to its excellent surface area and unique structure. It can be impregnated with various catalytic metals or metal oxides to enhance their activity and stability. This application is useful in chemical reactions like hydrogenation, oxidation, and carbon dioxide reduction, leading to improved reaction efficiency and cost-effectiveness.

- Aerospace and Defense: The lightweight and high strength properties of TF-CMPL make it suitable for the aerospace and defense industries. It serves as a structural material, thermal insulator, and heat sink in aircraft components and spacecraft. TF-CMPL’s ability to withstand high temperatures and harsh environments contributes to enhanced performance, fuel efficiency, and reduced vehicle weight.

- Filtration and Separation: TF-CMPL’s porous structure enables efficient filtration and separation of particles, contaminants, and impurities from liquids and gases. It finds applications in water treatment, oil and gas industries, and pharmaceuticals. Its high porosity and mechanical strength allow it to withstand high pressures and flow rates, ensuring effective filtration and separation processes.

- Biomedical Applications: In the biomedical field, TF-CMPL used in tissue engineering, drug delivery systems, and biosensors. Its biocompatibility, porosity, and mechanical properties make it suitable for scaffold fabrication in tissue engineering. TF-CMPL also acts as a carrier for controlled drug release, ensuring targeted and sustained drug delivery. Additionally, TF-CMPL-based biosensors exhibit high sensitivity and accuracy in detecting biomarkers and analytes.

Future Prospects:

The future prospects for TF-CMPL are promising, driven by ongoing research and advancements in materials science and nanotechnology. Researchers continuously explore methods to enhance the properties and performance of TF-CMPL. This includes improving mechanical strength, surface modification techniques, and integrating with other materials to expand its range of applications.

Furthermore, TF-CMPL expected to play a crucial role in the development of renewable energy systems. Its use in energy storage devices, such as advanced batteries and fuel cells, will contribute to the transition to clean and sustainable energy sources. Additionally, the growing demand for lightweight materials in industries like automotive and aerospace will drive the adoption of TF-CMPL due to its excellent mechanical properties.

Conclusion: Titanium fiber felt composite microporous layers demonstrate their versatility and potential in various industries, including energy storage, catalysis, aerospace, filtration, and biomedical applications. Ongoing research and development efforts expected to further enhance the properties and expand the range of applications for TF-CMPL. With its unique combination of lightweight, high strength, and porous structure, TF-CMPL holds great promise for future technological advancements and sustainable solutions.