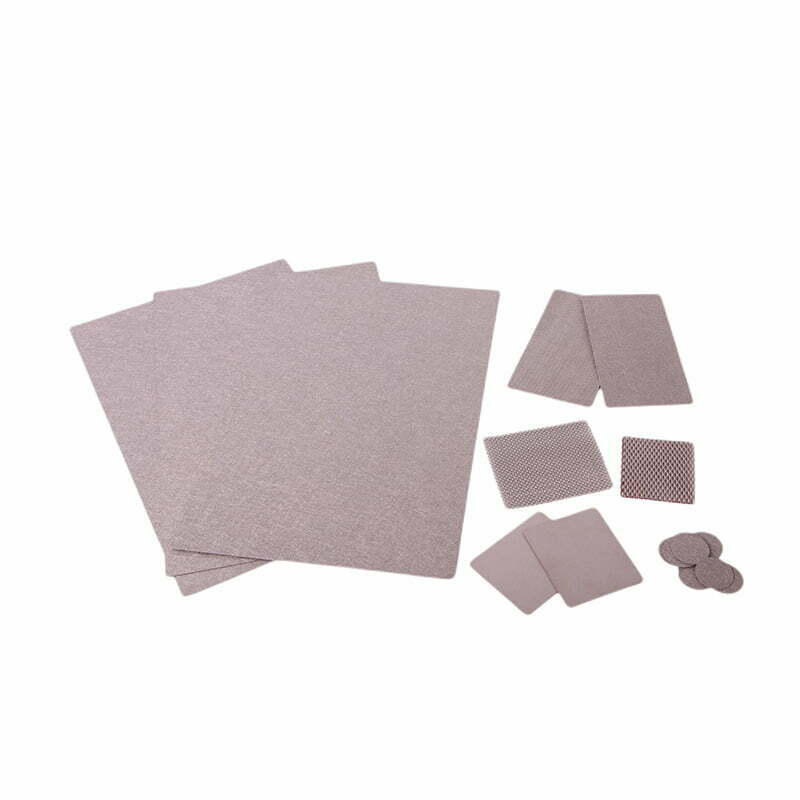

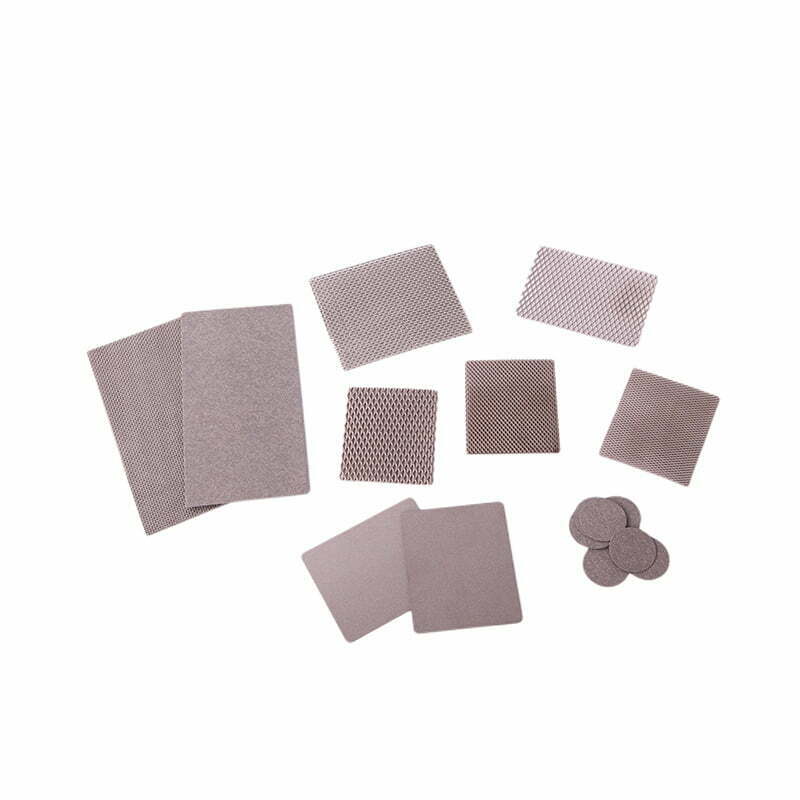

Nickel felt is a porous material made from pure nickel metal. It has a three-dimensional network structure with interconnected pores that provide high surface area and excellent fluid transport characteristics. Nickel felt possesses several unique properties such as high thermal conductivity, high electrical conductivity, good corrosion resistance, and high mechanical strength.

Due to its unique properties, nickel felt finds applications in various industries such as energy, electronics, aerospace, and biomedical. In the energy sector, nickel felt used as an electrode in batteries, fuel cells, and supercapacitors due to its high electrical conductivity and large specific surface area. For the electronics industry, it employed as a heat sink for electronic devices due to its high thermal conductivity. In aerospace, nickel felt used in rocket engines and as a lightweight structural material. In biomedical applications, nickel felt is utilized for tissue engineering, drug delivery, and biosensing.

The production methods of nickel felt include electroplating, chemical vapor deposition, and powder metallurgy. Electroplating involves the electrodeposition of nickel onto a substrate followed by the removal of the substrate to obtain pure nickel felt. Chemical vapor deposition involves the reaction of a nickel-containing precursor with a reducing agent to form nickel felt. Powder metallurgy involves the compaction and sintering of nickel powder to obtain nickel foam.

In conclusion, nickel felt is a versatile material with unique properties that make it ideal for various industrial applications. Its production methods have also evolved over time, making it easier to obtain in large quantities.